The hip joint, a type of ball-and-socket joint is a marvel of engineering. It allows us to walk, run, and climb with ease. However, when this joint suffers any injury or is hit by any disease, the complications that arise significantly impact the quality of our lives. Well, the orthopedic industry has an answer to this in the form of hip implants. They can replace the damaged part of the hip joint and provide natural-like hip movement. This blog post will discuss hip implants in detail.

What are Hip Implants?

Hip implants are medical devices used in hip replacement surgery, also known as hip arthroplasty. This surgery replaces the damaged parts of the hip joint with artificial components, restoring function and alleviating pain.

Who Needs Hip Implants?

The need for hip replacement implants can be assessed after analyzing the type and severity of the injury that affects our hip joint. However, there are several conditions that make hip replacement necessary. The most common is osteoarthritis, a degenerative joint disease that causes wearing down of the cartilage within the hip joint. This leads to bone rubbing on bone, resulting in pain, stiffness, and limited mobility. Besides this, some other conditions that may require hip surgery involving the application of hip implants include:

Rheumatoid arthritis: An autoimmune disease that inflames the joints, including the hips.

Avascular necrosis: A condition where the bone tissue in the femoral head dies due to a lack of blood supply.

Severe hip fractures: These can be particularly debilitating, especially in older adults.

What Are the Components of Hip Implants?

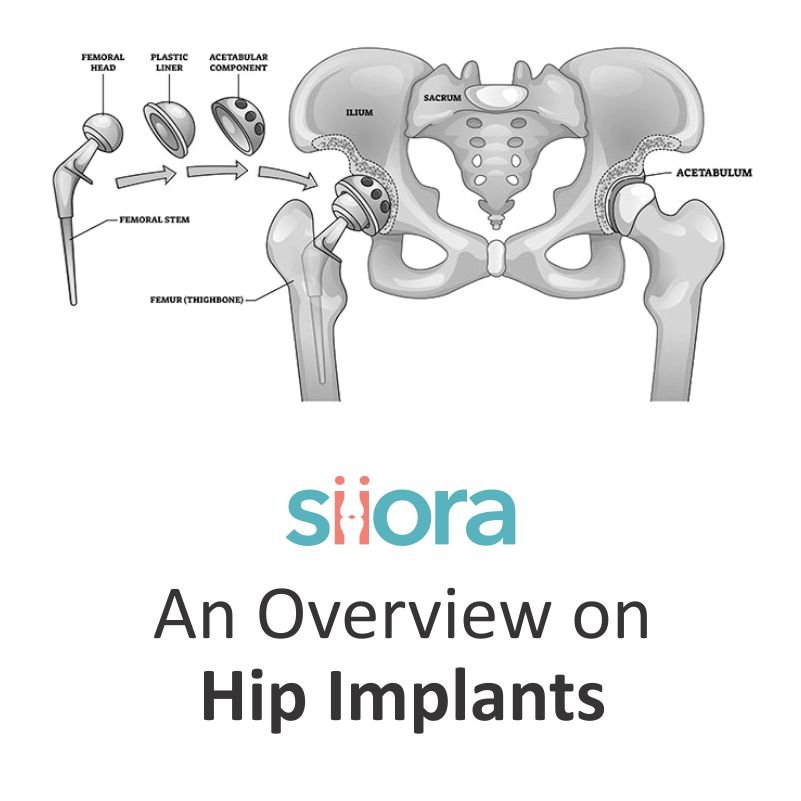

Hip implants consist of three main parts:

The stem

The stem is made of durable medical-grade metal alloys like titanium or cobalt-chrome. It is inserted into the hollow center of the femur (thigh bone) to provide stability.

The ball

This replaces the damaged femoral head and can be made of ceramic, metal (usually cobalt-chrome), or highly polished metal.

The socket

Replacing the worn-out cartilage in the acetabulum (hip socket), the socket typically consists of a metal shell lined with a wear-resistant plastic material like polyethylene.

There are various combinations of materials used for the ball and socket, each with its own advantages and disadvantages. Here’s a breakdown of some common bearing surfaces:

Metal-on-polyethylene

This is a widely used combination. The metal ball offers good wear resistance, while the polyethylene liner provides a smooth gliding surface. However, there’s a small risk of tiny polyethylene particles wearing off, which might cause inflammation in some patients.

Ceramic-on-polyethylene

Ceramic balls are even smoother and more wear-resistant than metal, potentially reducing the risk of wear debris. However, ceramic is more brittle and there’s a slightly higher risk of fracture.

Ceramic-on-ceramic

This offers the smoothest articulation and potentially the longest lifespan. However, the initial cost is higher, and there’s a small possibility of both components fracturing.

How Hip Implants are Applied?

During hip replacement surgery, general anesthesia is given to the patient. The surgeon will make an incision on the hip and carefully remove the damaged bone and cartilage. The new components will then be implanted using various techniques, depending on the specific needs of the patient. In some cases, bone cement might be used to secure the stem in the femur. Modern advancements also allow for cementless implants that rely on a press-fit technique for stability.

How Recovery and Rehabilitation Occurs After Hip Replacement Surgery?

Following surgery, physical therapy plays a crucial role in regaining strength, mobility, and balance. Patients will typically begin with passive exercises while still in the hospital, gradually progressing to active exercises as they recover. Most people can return home within a few days of surgery, but a complete recovery can take several weeks or months.

What Are the Benefits of Using Hip Implants?

Hip replacement surgery offers significant benefits for patients suffering from chronic hip pain and limited mobility. These include:

Pain relief: The primary goal is to alleviate pain significantly, allowing patients to return to daily activities with greater ease.

Improved mobility: Increased flexibility and range of motion in the hip joint enable better walking, climbing stairs, and performing everyday tasks.

Enhanced quality of life: Reduced pain and improved mobility lead to a significant improvement in overall well-being and participation in activities that were previously difficult or impossible.

What Risks and Complications Are Associated with Hip Replacement Implants?

As with any surgery, hip replacement carries some risks, although they are relatively uncommon. These include:

- Infection

- Bleeding

- Blood clots

- Nerve damage

- Dislocation of the implant

- Loosening of the implant (may require revision surgery)

Conclusion

Hip implants are a remarkable innovation in orthopedic surgery, offering a life-changing solution for individuals struggling with severe hip pain and dysfunction. With careful patient selection, proper surgical technique, and dedicated rehabilitation, hip replacement surgery can help patients regain mobility, reduce pain, and improve their quality of life. Newer and advanced hip implants are also known to have an excellent lifespan. Hence, you need not worry about the durability of these implants. The only thing you need to consider is to find an experienced orthopedic surgeon and a reliable orthopedic implant manufacturer.

About Siora

Siora Surgicals Pvt. Ltd. is a trustworthy orthopedic device manufacturer in India operating for over 30 years. Having hundreds of different types of trauma implants under its belt, Siora supplies them under 20+ different categories. All implants are manufactured and tested to meet international standards in Siora’s technologically advanced manufacturing unit established in RAI District, Sonepat, Haryana.

The company has a skilled team of professionals that ensures precision testing of each product after coming out of the production unit. All implants are tested for bioburden in the microbiology lab and packed in an ISO class 10,000 cleanroom to eliminate the risk of contamination. The company has served clients in over 50 countries and is looking for more distributors across the globe.

Siora will also be exhibiting with its newer and better range of orthopedic implants at the Florida International Medical Expo (FIME) 2024. You can explore our range of trauma implants & instruments at booth X21.